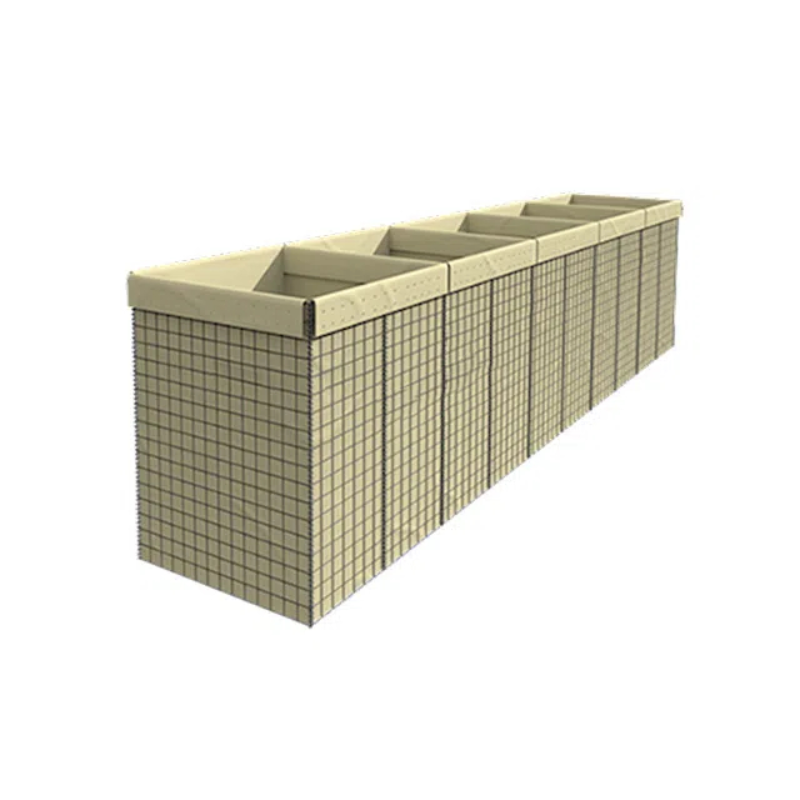

Defensive barrier

Defensive barriers are physical structures designed to protect people, property, and critical infrastructure from threats such as vehicle attacks, intrusions, or natural disasters. They vary widely in design, materials, and strength to address specific risks. Below is a detailed breakdown of common types, specifications, and applications:

- Product Details

- Technical Specification

1. Types of Defensive Barriers

A. Vehicle Barriers

Bollards

Materials: Steel, concrete, stainless steel, or composite materials.

Specifications:

Crash Rating: ASTM F2656 (K12, K8, K4 ratings for vehicle impact resistance).

Height: 30–48 inches (76–122 cm).

Diameter: 6–12 inches (15–30 cm).

Installation: Fixed (embedded in concrete) or retractable (hydraulic/electric).

Applications:

Perimeter security for government buildings, airports, stadiums.

Pedestrian zones, storefronts.

Jersey Barriers

Materials: Reinforced concrete or polyethylene (plastic).

Specifications:

Dimensions: 10 ft long x 32" tall x 24" base (3 m x 81 cm x 61 cm).

Weight: 4,000–6,000 lbs (1,800–2,700 kg) for concrete.

Crash Rating: ASTM C825 for impact resistance.

Applications:

Temporary traffic control at construction sites.

Perimeter security for events or military checkpoints.

Crash Beams/Gates

Materials: High-strength steel or aluminum.

Specifications:

Impact Resistance: Rated for 15,000–30,000 lb (6,800–13,600 kg) vehicles.

Deployment: Manual, hydraulic, or automated.

Applications:

Military bases, embassies, nuclear facilities.

B. Perimeter Barriers

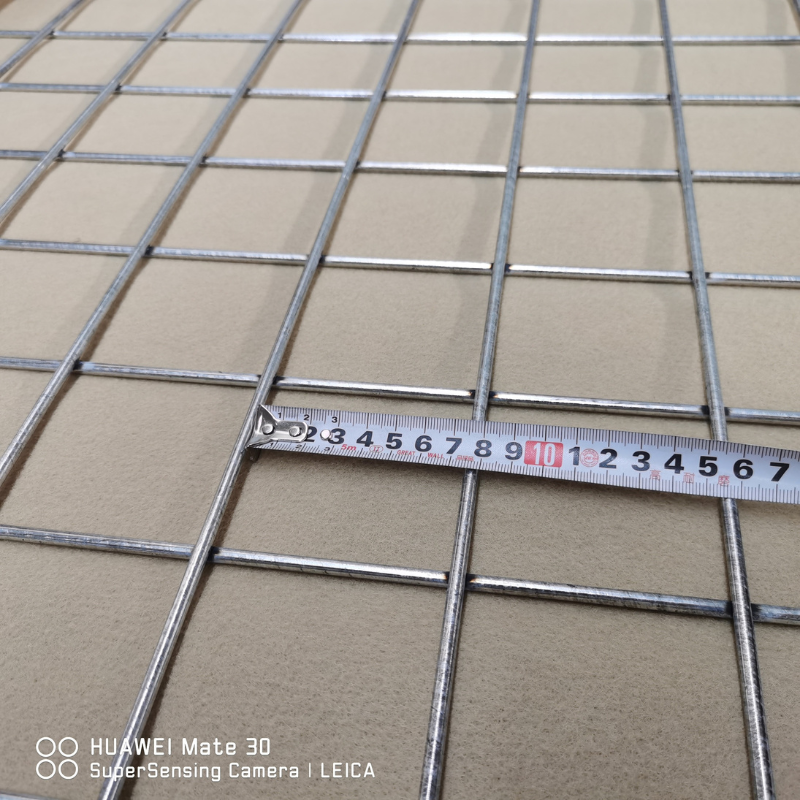

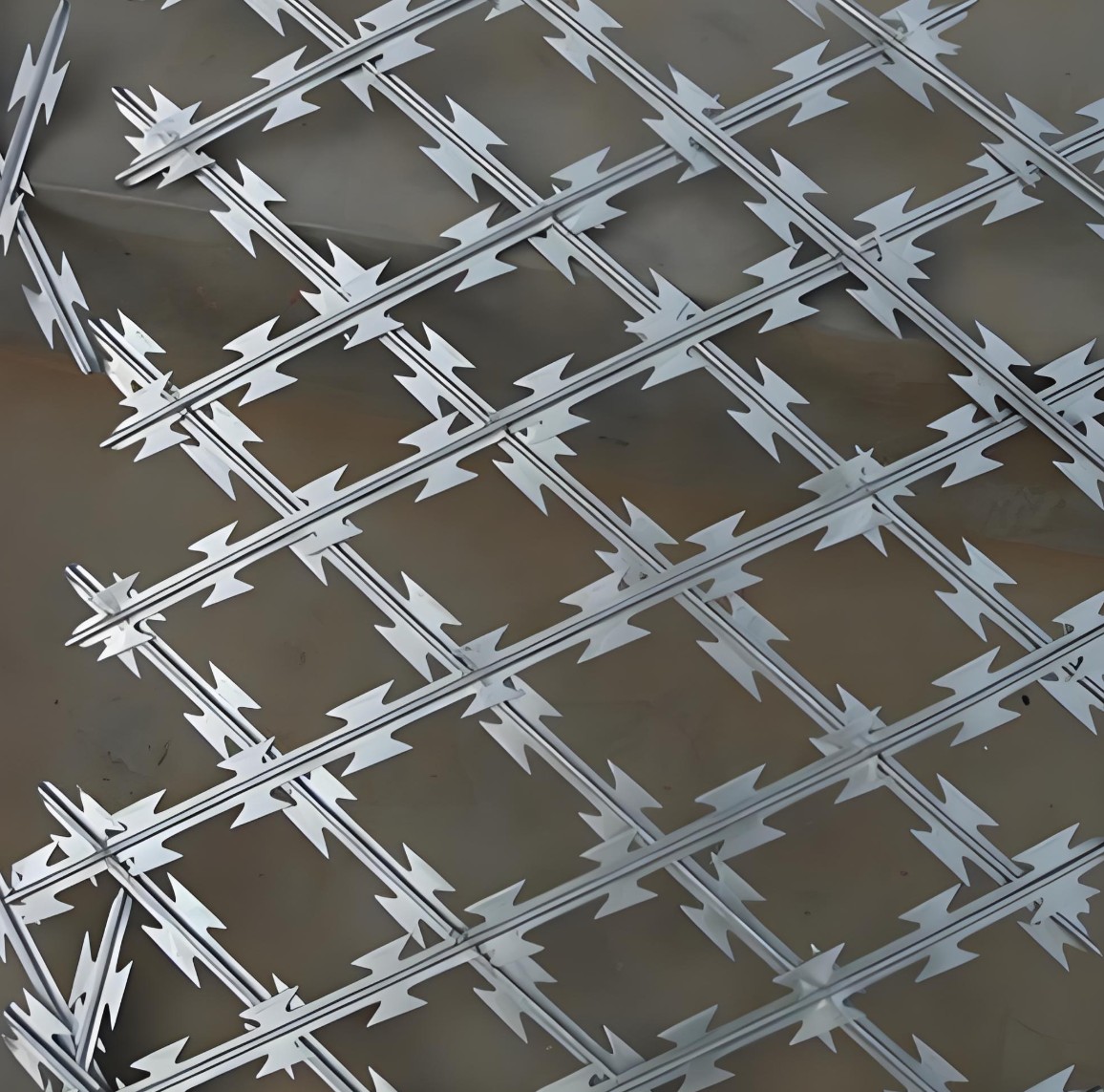

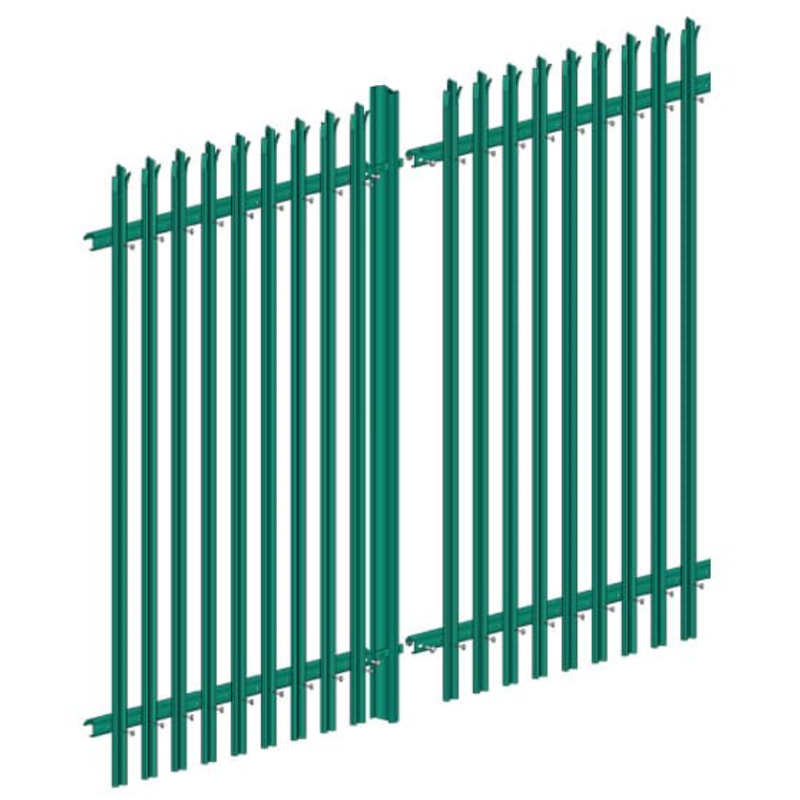

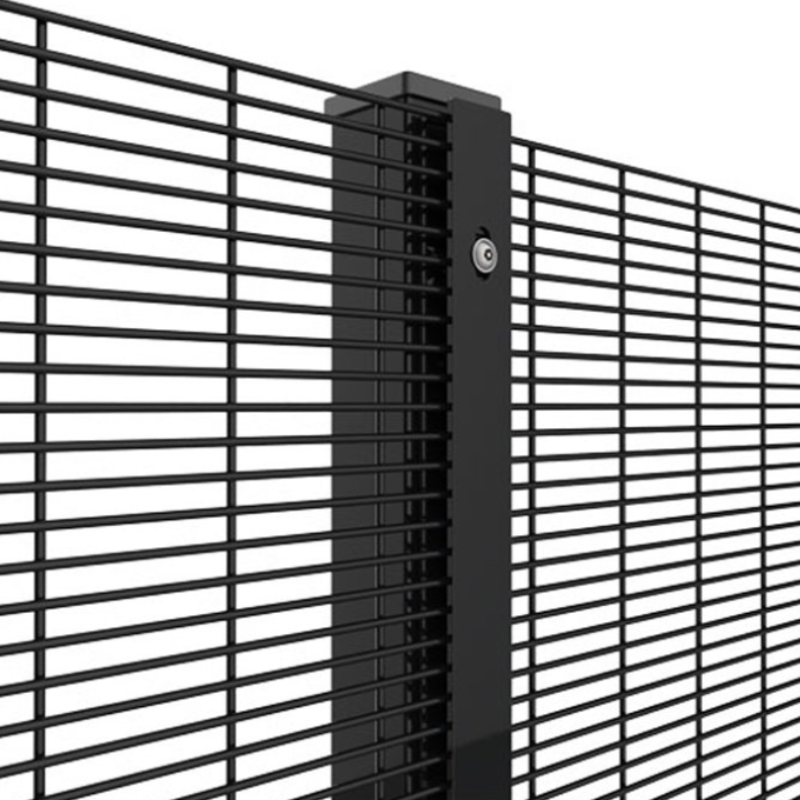

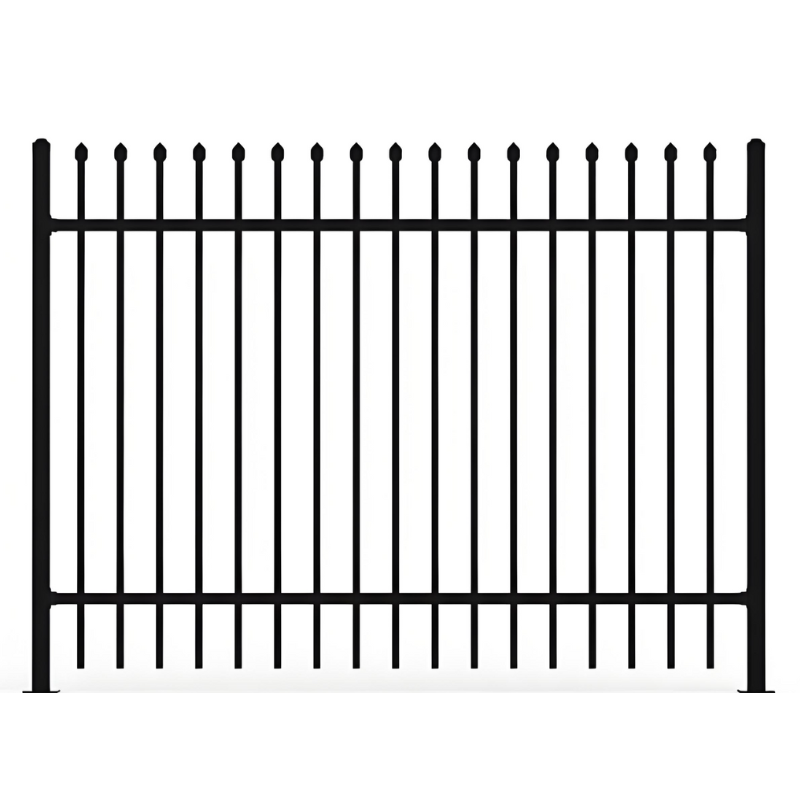

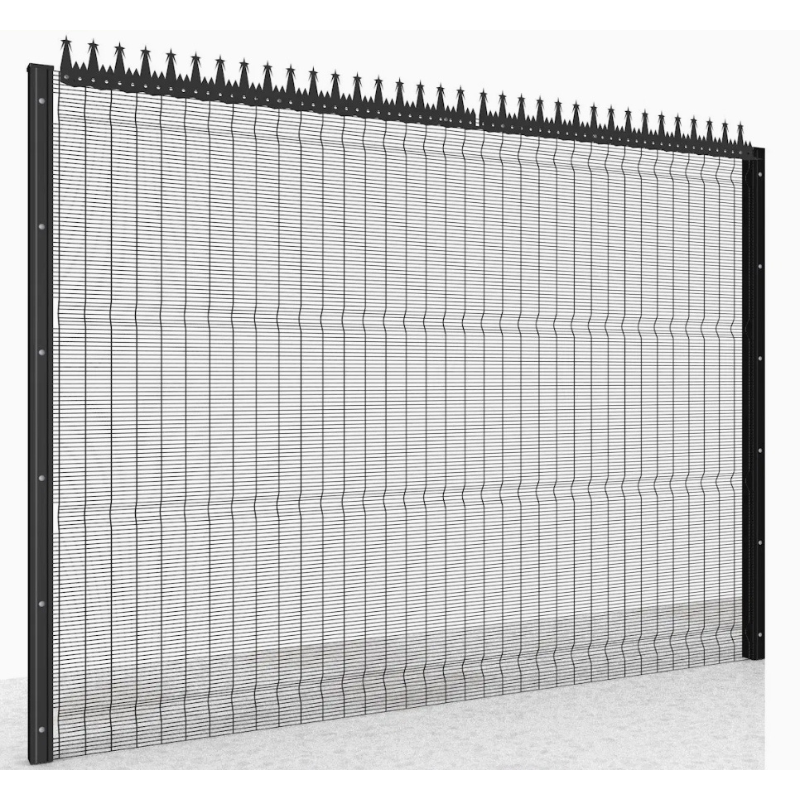

Security Fences

Types: Chain-link, welded mesh, palisade, or anti-climb.

Specifications:

Height: 6–20 ft (1.8–6 m).

Material: Galvanized steel, stainless steel, or vinyl-coated.

Toppings: Razor wire, barbed tape, or anti-cut mesh.

Applications:

Prisons, industrial sites, data centers.

Concrete Walls

Specifications:

Thickness: 6–12 inches (15–30 cm).

Reinforcement: Steel rebar or fiber-reinforced concrete.

Blast Resistance: Rated for explosions (e.g., UL 752 ballistic standards).

Applications:

Military installations, high-risk government facilities.

Hydraulic Barriers

Specifications:

Rise Time: 3–10 seconds.

Load Capacity: Up to 7,500 kg (16,500 lbs).

Applications:

Vehicle access control at secure facilities.

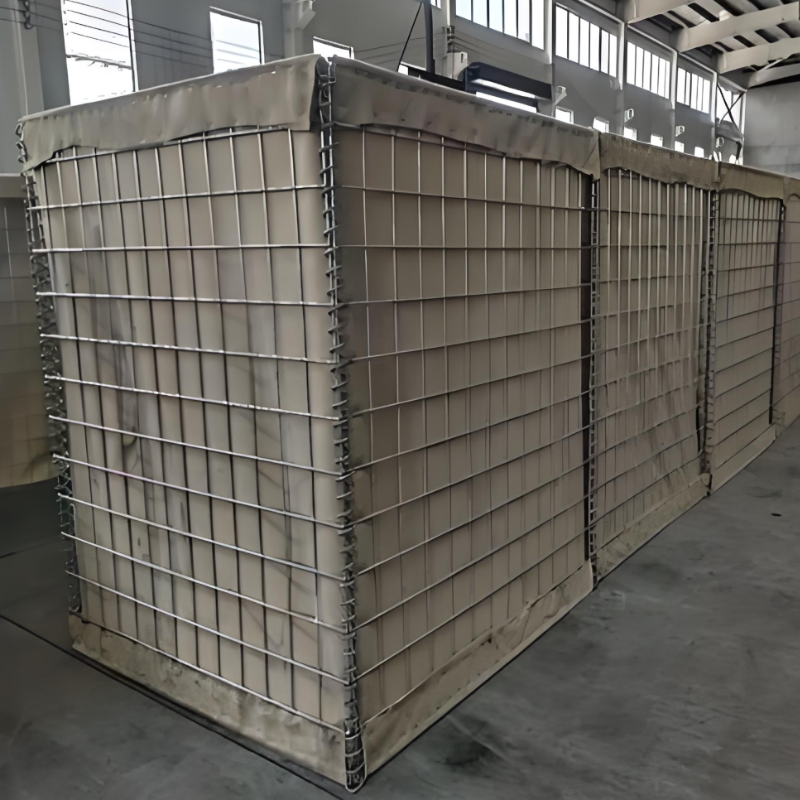

C. Natural/Blast Mitigation Barriers

Earth Berms

Specifications:

Slope: 45–60 degrees.

Material: Compacted soil, gravel, or sandbags.

Applications:

Blast protection for military storage areas.

Flood control.

Water-Filled Barriers

Specifications:

Material: Polyethylene or steel.

Capacity: 500–2,000 liters per segment.

Applications:

Crowd control, construction zones, event security.

2. Key Specifications

Crash/Impact Ratings:

ASTM F2656: Rates barriers from K4 (passenger cars) to K12 (heavy trucks).

ISO/IWA 14-1: International standards for vehicle security barriers.

Blast Resistance:

UL 752: Ballistic ratings for explosions (Level 1–Level 10).

Corrosion Resistance:

Galvanizing: Class 3 (≥245 g/m² zinc coating).

Stainless Steel: Grade 304/316 for coastal environments.

3. Applications by Threat Level

Threat Type Recommended Barrier Example Use Cases

Vehicle Ramming Crash-rated bollards (K12), Jersey barriers Embassies, pedestrian malls

Forced Entry Anti-climb fences, razor wire Prisons, substations

Blast/Explosives Reinforced concrete walls, earth berms Military bases, fuel depots

Crowd Control Water-filled barriers, steel fencing Protests, concerts, sports events

Coastal Erosion Riprap (rock barriers), sea walls Shoreline protection

4. Hybrid and Smart Barriers

Sensor-Integrated Barriers:

Motion detectors, cameras, or AI-powered surveillance linked to barriers.

Applications: Smart cities, critical infrastructure.

Retractable/Adaptive Systems:

Barriers that lower or rise based on real-time threats (e.g., automated bollards).

5. Environmental Considerations

Coastal Areas: Stainless steel or polymer-coated barriers.

Extreme Temperatures: Thermal-resistant materials (e.g., fiber-reinforced composites).

Aesthetics: Decorative bollards or green walls (vegetated barriers).

6. Cost and Maintenance

详见表格

7. Standards and Certifications

ASTM F2656: Vehicle impact resistance.

ISO 1461: Hot-dip galvanizing for corrosion protection.

DOS K-Ratings: U.S. Department of State standards for embassy security.

8. Conclusion

Defensive barriers are essential for mitigating risks ranging from terrorism to natural disasters. Selection depends on:

Threat Level: Match barrier strength to potential risks (e.g., K12 bollards for truck attacks).

Environment: Use corrosion-resistant materials in harsh climates.

Cost vs. Lifespan: Balance initial investment with long-term durability.

For maximum protection, combine physical barriers with technology (e.g., sensors, CCTV) and procedural security measures. Always comply with local regulations and consult engineers for high-risk installations.

| Barrier Type | Cost Range | Maintenance Needs |

| Bollards | 1,000–1,000–15,000+ each | Annual inspections, lubrication |

| Jersey Barriers | 100–100–500 per unit | Minimal (concrete) |

| Security Fences | 20–20–50 per linear ft | Rust removal, topping replacements |

| Hydraulic Barriers | 50,000–50,000–200,000+ | Monthly system checks |

barbed wire

barbed wire  Razor wire

Razor wire  Defensive barrier

Defensive barrier  Putanka wire

Putanka wire  metal fence

metal fence  Temporary fence

Temporary fence  Security fence

Security fence  Palisade tence

Palisade tence  Anti climb fence

Anti climb fence  Chain link fence

Chain link fence  Aluminum fence

Aluminum fence  Ornamental fence-12

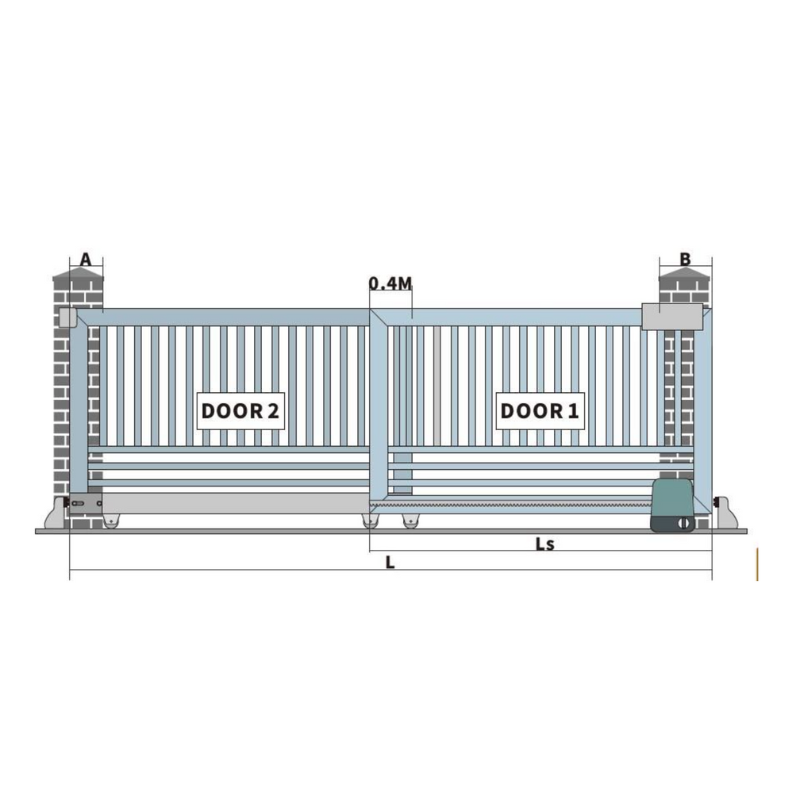

Ornamental fence-12  Metal fence gate

Metal fence gate  Fence spikes

Fence spikes  Edge protection barriers

Edge protection barriers  Airport Perimeter Fencing

Airport Perimeter Fencing  Temporary Fence System

Temporary Fence System  Barbed Wire Fencing

Barbed Wire Fencing  Prison Security Fencing

Prison Security Fencing  MZP Putanka Wire

MZP Putanka Wire  Rapid Deployment Barrier System

Rapid Deployment Barrier System  Military Defensive Solution

Military Defensive Solution