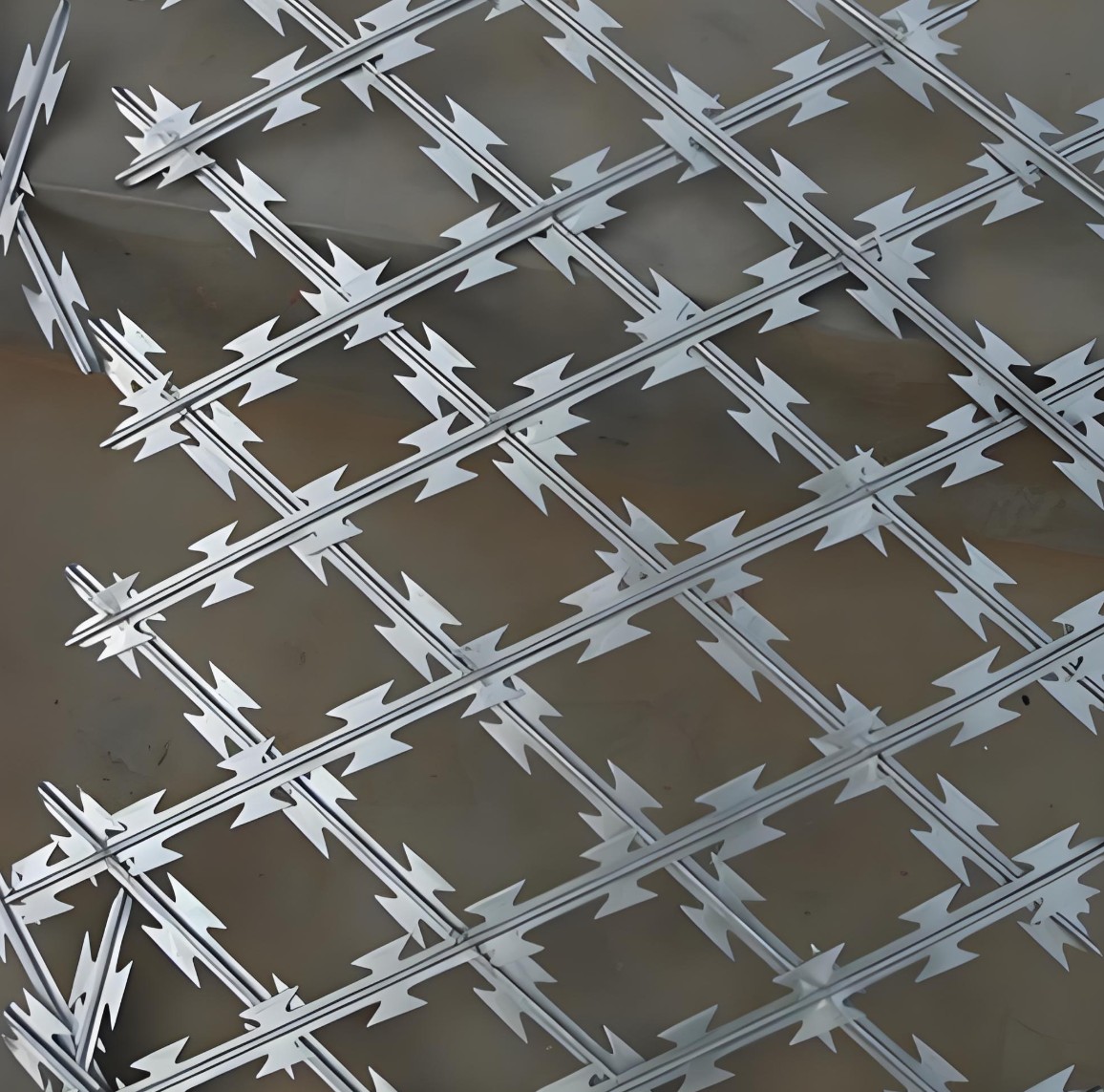

barbed wire

Barbed wire remains a versatile, economical solution for agriculture, security, and property protection. By selecting the right material, gauge, and spacing, users can tailor it to their specific needs, balancing durability, cost, and effectiveness. Its simplicity and adaptability ensure continued relevance in modern fencing systems.

- Product Details

- Technical Specification

1. Key Components

Wire Strands: Typically made of galvanized steel, stainless steel, or polymer-coated steel for durability.

Barbs: Sharp projections (usually 2- or 4-pointed) spaced regularly to deter crossing.

Twist Pattern: Wires are twisted together to hold barbs in place and add structural strength.

2. Common Materials

Galvanized Steel: Zinc-coated to resist rust; classified as Class 1 (light), 2 (medium), or 3 (heavy-duty).

Stainless Steel: Used in corrosive environments (e.g., coastal regions).

PVC-Coated Steel: Adds weather resistance and color options (e.g., green, black).

3. Specifications

Gauge (Thickness):

12.5 Gauge (2.77 mm): Heavy-duty for livestock and high-security areas.

14 Gauge (2.03 mm): Lightweight, ideal for temporary fencing.

Barb Spacing:

4–6 inches (10–15 cm): Tighter spacing (4") for security; wider (5–6") for agriculture.

Tensile Strength:

Standard: 40,000–80,000 psi.

High-tensile: Up to 220,000 psi for minimal sagging.

4. Applications

Agriculture:

Contains cattle, sheep, and horses.

Uses 12.5-gauge galvanized wire with 5" barb spacing.

Security:

Protects prisons, military sites, and industrial zones.

Combines high-tensile wire, 4" barb spacing, and PVC coatings.

Boundary Marking:

Defines property lines and deters trespassers.

5. Installation Tips

Posts: Use sturdy wooden or metal posts spaced 10–15 feet apart.

Tensioning: High-tensile wire requires tensioning tools to prevent sagging.

Safety: Wear gloves and protective gear to avoid injuries from barbs.

6. Standards and Certifications

ASTM A121: Governs galvanized barbed wire quality in the U.S.

ISO 13440: International standards for agricultural fencing.

7. Environmental Considerations

Coastal Areas: Use stainless steel or Class 3 galvanized wire.

UV Exposure: Opt for PVC-coated wire to prevent degradation.

| GALVANIZED BARBED WIRE SPECIFICATIONS | ||||

| Line Wire and Barb Wire Diameter | Approximate Length per Kilogram in meter | |||

| (BWG) | Barbs Spacing 3'' | Barbs Spacing 4'' | Barbs Spacing 5'' | Barbs Spacing 6'' |

| 12 x 12 | 6.0617 | 6.759 | 7.27 | 7.6376 |

| 12 x 14 | 7.3335 | 7.9051 | 8.3015 | 8.5741 |

| 12.5 x 12.5 | 6.9223 | 7.719 | 8.3022 | 8.7221 |

| 12.5 x 14 | 8.1096 | 8.814 | 9.2242 | 9.562 |

| 13 x 13 | 7.9808 | 8.899 | 9.5721 | 10.0553 |

| 13 x 14 | 8.8448 | 9.6899 | 10.2923 | 10.7146 |

| 13.5 x 14 | 9.6079 | 10.6134 | 11.4705 | 11.8553 |

| 14 x 14 | 10.4569 | 11.659 | 12.5423 | 13.1752 |

| 14.5 x 14.5 | 11.9875 | 13.3671 | 14.3781 | 15.1034 |

| 15 x 15 | 13.8927 | 15.4942 | 16.6666 | 17.507 |

| 15.5 x 15.5 | 15.3491 | 17.1144 | 18.406 | 19.3386 |

barbed wire

barbed wire  Razor wire

Razor wire  Defensive barrier

Defensive barrier  Putanka wire

Putanka wire  metal fence

metal fence  Temporary fence

Temporary fence  Security fence

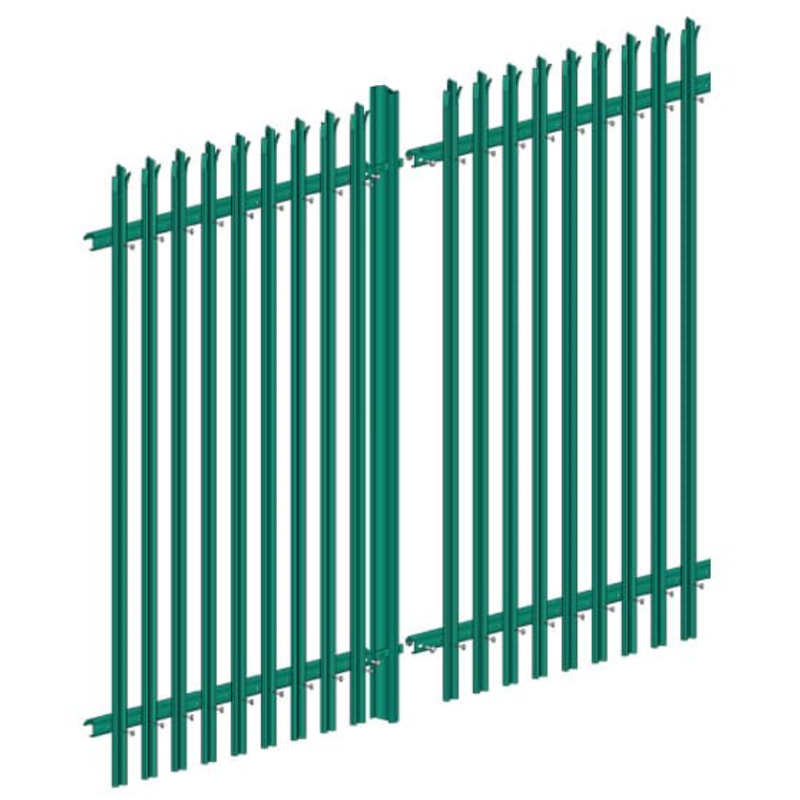

Security fence  Palisade tence

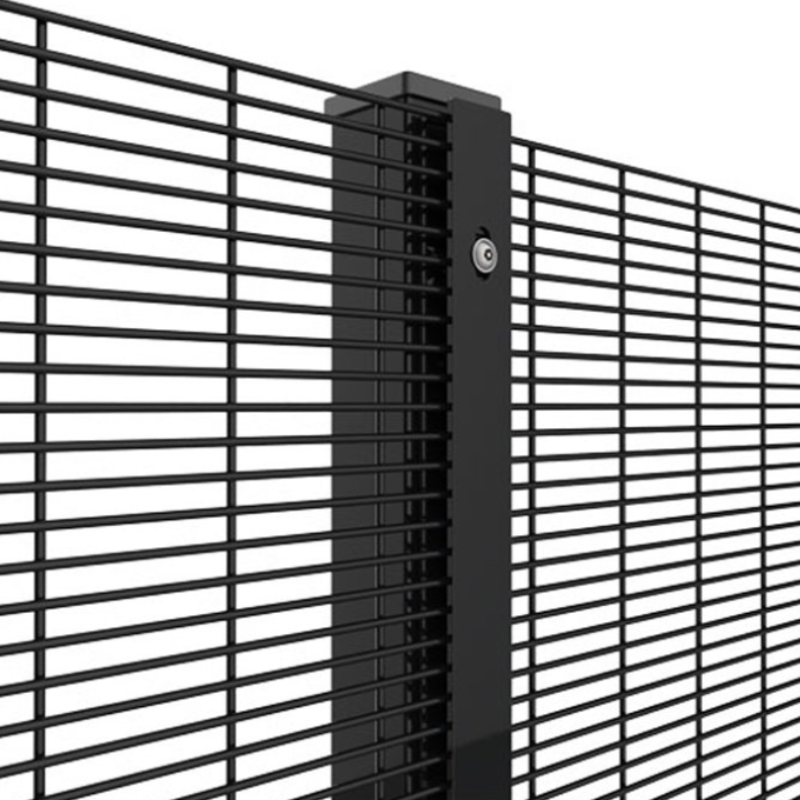

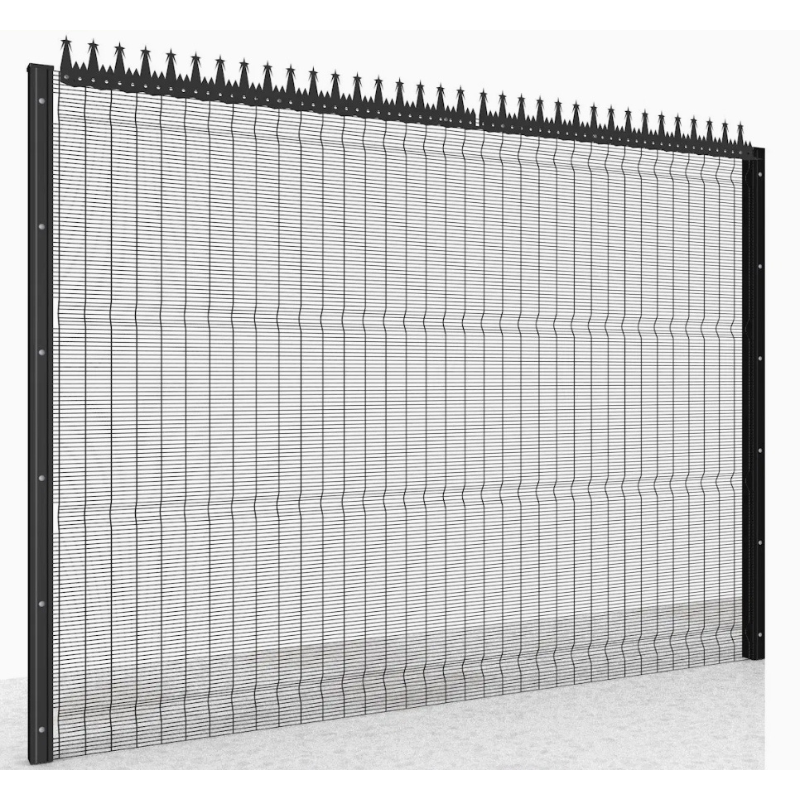

Palisade tence  Anti climb fence

Anti climb fence  Chain link fence

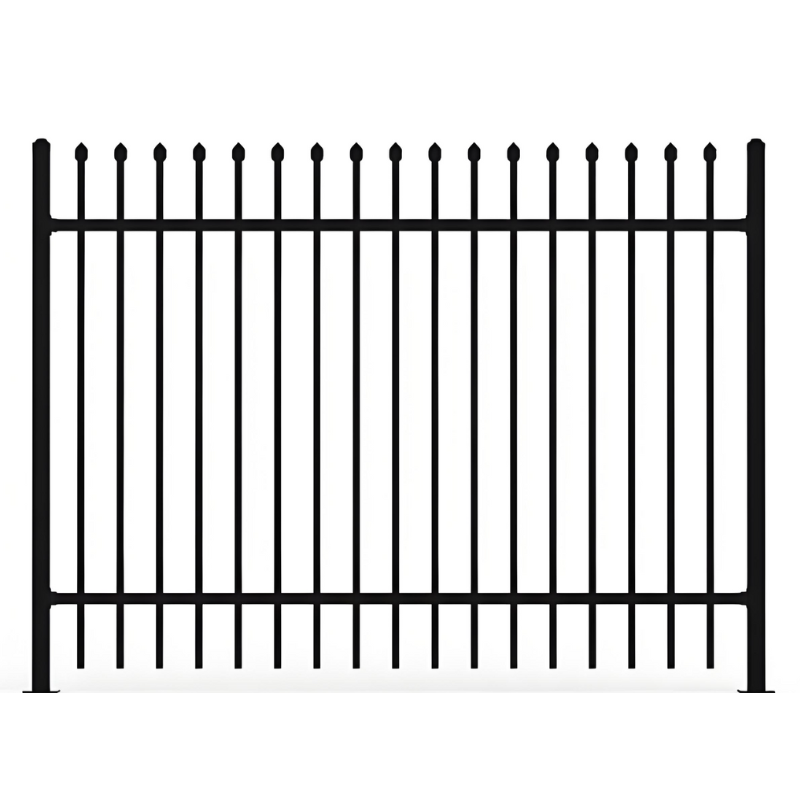

Chain link fence  Aluminum fence

Aluminum fence  Ornamental fence-12

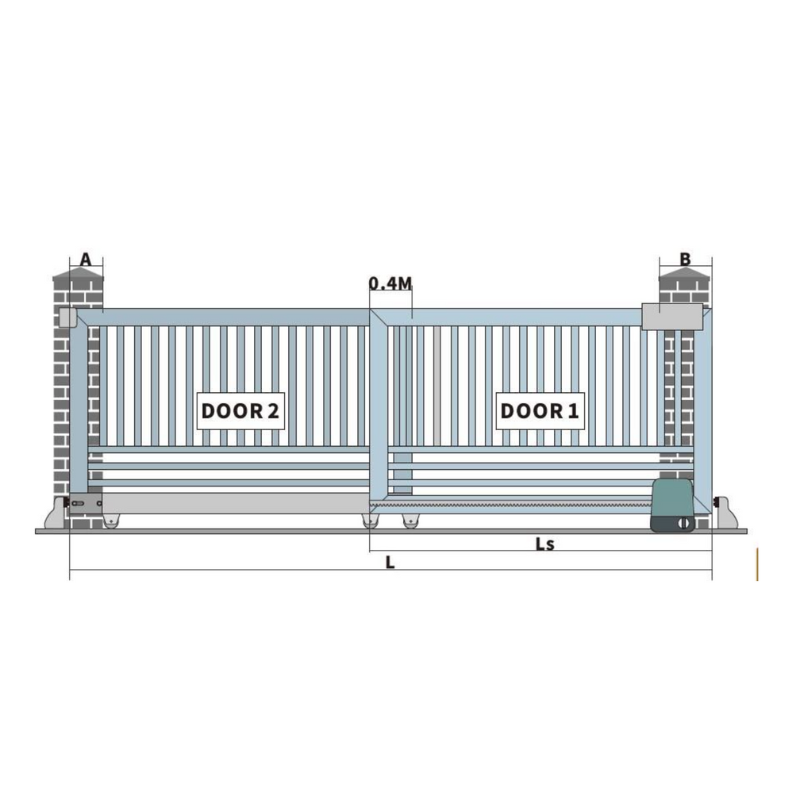

Ornamental fence-12  Metal fence gate

Metal fence gate  Fence spikes

Fence spikes  Edge protection barriers

Edge protection barriers  Airport Perimeter Fencing

Airport Perimeter Fencing  Temporary Fence System

Temporary Fence System  Barbed Wire Fencing

Barbed Wire Fencing  Prison Security Fencing

Prison Security Fencing  MZP Putanka Wire

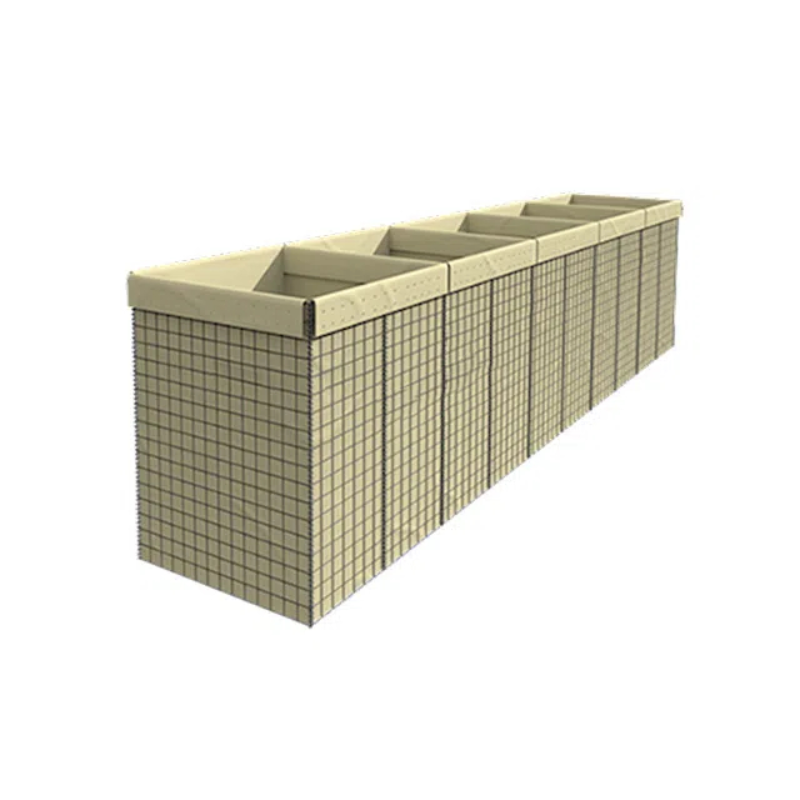

MZP Putanka Wire  Rapid Deployment Barrier System

Rapid Deployment Barrier System  Military Defensive Solution

Military Defensive Solution